Match List – I with List – II:

| List – I | List – II |

| :--- | :--- |

| (a) Mercury | (i) Vapour phase refining |

| (b) Copper | (ii) Distillation Refining |

| (c) Silicon | (iii) Electrolytic Refining |

| (d) Nickel | (iv) Zone Refining

Choose the most appropriate answer from the option given below:

Match List – I with List – II:

| List – I | List – II |

| :--- | :--- |

| (a) Mercury | (i) Vapour phase refining |

| (b) Copper | (ii) Distillation Refining |

| (c) Silicon | (iii) Electrolytic Refining |

| (d) Nickel | (iv) Zone Refining

Choose the most appropriate answer from the option given below:

The following depicts a chemical reaction leading to a Major Product Y.

Mercury has low boiling point so is refined by distillation method.

Copper refining is done through electrolytic refining.

Silicon is refined by zone refining method.

Nickel is refined by vapour phase refining.

Similar Questions for you

Na+ C + N + S ®NaSCN

Fe3+ + SCN–

In the metallurgy of aluminium, purified Al2O3 is mixed with Na3AIF6 or CaF2 which lowers the melting point of the mixture and brings conductivity.

Ellingham diagram explains the feasibility of reduction process not the kinetics of process.

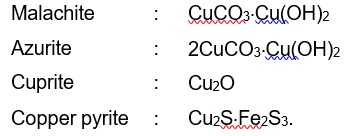

Malachite : CuCO3.Cu (OH)2

Azurite : 2CuCO3.Cu (OH)2

Cuprite : Cu2O

Copper pyrite : Cu2S.Fe2S3.

Taking an Exam? Selecting a College?

Get authentic answers from experts, students and alumni that you won't find anywhere else.

On Shiksha, get access to

Learn more about...

Chemistry Ncert Solutions Class 12th 2023

View Exam DetailsMost viewed information

SummaryDidn't find the answer you were looking for?

Search from Shiksha's 1 lakh+ Topics

Ask Current Students, Alumni & our Experts

Have a question related to your career & education?

See what others like you are asking & answering