24. Zone refining is based on the principle that

(i) Impurities of low boiling metals can be separated by distillation.

(ii) Impurities are more soluble in molten metal than in solid metal.

(iii) Different components of a mixture are differently adsorbed on an adsorbent.

(iv) Vapors of volatile compounds can be decomposed in pure metal.

24. Zone refining is based on the principle that

(i) Impurities of low boiling metals can be separated by distillation.

(ii) Impurities are more soluble in molten metal than in solid metal.

(iii) Different components of a mixture are differently adsorbed on an adsorbent.

(iv) Vapors of volatile compounds can be decomposed in pure metal.

-

1 Answer

-

24. Option (ii)

Purification of metal crystals by making a thin region of crystal undergo melting is known as Zone refining. The molten crystal is then moved up along the crystal to get pure form of it. This process is used to get pure form of Silicon and Germanium. Basic principle of the zone refining process is that the impurities are more soluble in molten metal than solid metal to get pure form of metal.

Similar Questions for you

is the temperature Co-efficient of cell. The cell having less variation of EMF, with respect to temperature have high efficiency.

Below 1350° C, Mg can reduce Al2O3 and above 1350°C, Al can reduce MgO (from Ellingham diagram).

Melting and boiling point of Mg are lower than that of Al.

In ores/mineral available earthy and undesired impurities are gangue

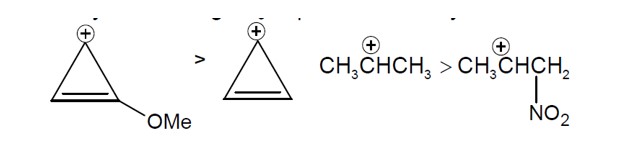

Sol. Reactivity towards depend on stability of carbocation formed

Leaching involves the given reaction,

Here, O2 is required for formation of Au (l) cyanide complex but no complex in absence of O2.

In above displacement reaction, Zn is oxidized.

Taking an Exam? Selecting a College?

Get authentic answers from experts, students and alumni that you won't find anywhere else

Sign Up on ShikshaOn Shiksha, get access to

- 66k Colleges

- 1.2k Exams

- 681k Reviews

- 1800k Answers