37. In the Froth Floatation process, zinc sulfide and lead sulfide can be separated by

(i) Using collectors.

(ii) Adjusting the proportion of oil to water.

(iii) Using depression.

(iv) Using froth stabilizers.

37. In the Froth Floatation process, zinc sulfide and lead sulfide can be separated by

(i) Using collectors.

(ii) Adjusting the proportion of oil to water.

(iii) Using depression.

(iv) Using froth stabilizers.

-

1 Answer

-

37. Option (ii) and (iii)

It is possible to separate two sulfide ores using the froth floatation process by adjusting the proportion of oil to water or by using 'depressants.' In the case of an ore containing ZnS and PbS, for example, the depressant used is NaCN.

Similar Questions for you

is the temperature Co-efficient of cell. The cell having less variation of EMF, with respect to temperature have high efficiency.

Below 1350° C, Mg can reduce Al2O3 and above 1350°C, Al can reduce MgO (from Ellingham diagram).

Melting and boiling point of Mg are lower than that of Al.

In ores/mineral available earthy and undesired impurities are gangue

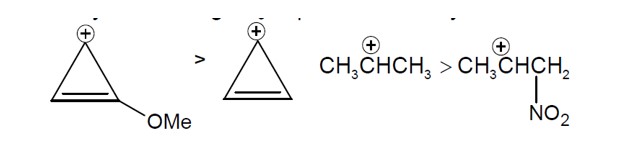

Sol. Reactivity towards depend on stability of carbocation formed

Leaching involves the given reaction,

Here, O2 is required for formation of Au (l) cyanide complex but no complex in absence of O2.

In above displacement reaction, Zn is oxidized.

Taking an Exam? Selecting a College?

Get authentic answers from experts, students and alumni that you won't find anywhere else

Sign Up on ShikshaOn Shiksha, get access to

- 66k Colleges

- 1.2k Exams

- 681k Reviews

- 1800k Answers