Match List – I with List – II:

| List - I | List - II |

| (a) Concentration of Ag ore | (i) Reverberatory furnace |

| (b) Blast furnace | (ii) Pig iron |

| (c) Blister copper | (iii) Leaching with dilute NaCN solution |

| (d) Froth floatation method | (iv) Sulfide ores |

Choose the correct answer from the options given below:

Match List – I with List – II:

| List - I | List - II |

| (a) Concentration of Ag ore | (i) Reverberatory furnace |

| (b) Blast furnace | (ii) Pig iron |

| (c) Blister copper | (iii) Leaching with dilute NaCN solution |

| (d) Froth floatation method | (iv) Sulfide ores |

Choose the correct answer from the options given below:

Option 1 -

(a)–(iii), (b)–(ii), (c)–(i), (d)–(iv)

Option 2 -

(a)–(iii), (b)–(iv), (c)–(i), (d)–(ii)

Option 3 -

(a)–(iv), (b)–(i), (c)–(iii), (d)–(ii)

Option 4 -

(a)–(iv), (b)–(iii), (c)–(ii), (d)–(i)

-

1 Answer

-

Correct Option - 1

Detailed Solution:(A) Concentration of Ag & Au done by NaCN. It is known as Mac Arthur Process (cyanide process)

(B) Blast furnace produces pig Fe.

(C) Blister Cu → Reverberatory furnace. In this furnace smelting & roasting of ore take place

CuFeS? + O? → Cu? O + FeO

(D) Froth floatation process is used for concentration of sulphide ores.

Similar Questions for you

Na+ C + N + S ®NaSCN

Fe3+ + SCN–

In the metallurgy of aluminium, purified Al2O3 is mixed with Na3AIF6 or CaF2 which lowers the melting point of the mixture and brings conductivity.

Ellingham diagram explains the feasibility of reduction process not the kinetics of process.

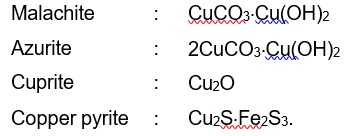

Malachite : CuCO3.Cu (OH)2

Azurite : 2CuCO3.Cu (OH)2

Cuprite : Cu2O

Copper pyrite : Cu2S.Fe2S3.

Taking an Exam? Selecting a College?

Get authentic answers from experts, students and alumni that you won't find anywhere else

Sign Up on ShikshaOn Shiksha, get access to

- 66k Colleges

- 1.2k Exams

- 681k Reviews

- 1800k Answers